Bioforce is a biomethane production company whose core activity is processing biomass, including animal by-products, into environmentally friendly biomethane. Bioforce’s solutions include the design and construction of biomethane plants and CNG filling stations, commissioning, 24/7 operations, and maintenance. In Tallinn, Bioforce operates two large refuelling stations that serve city public transport powered by gas buses and sell over 150 GWh of gas annually, significantly reducing the environmental footprint of public transport.

A production and distribution model based on the principles of the circular economy naturally supports a paperless logistics chain. Bioforce’s strategic goal is to strengthen local green gas production, reduce dependence on imported fuels, and improve energy security. As Bioforce representative Henry Uljas has emphasised, capturing methane and processing it into biogas is critical for achieving climate goals, as methane is at least 28 times more harmful than CO₂.

Logistics Challenges Before Waybiller

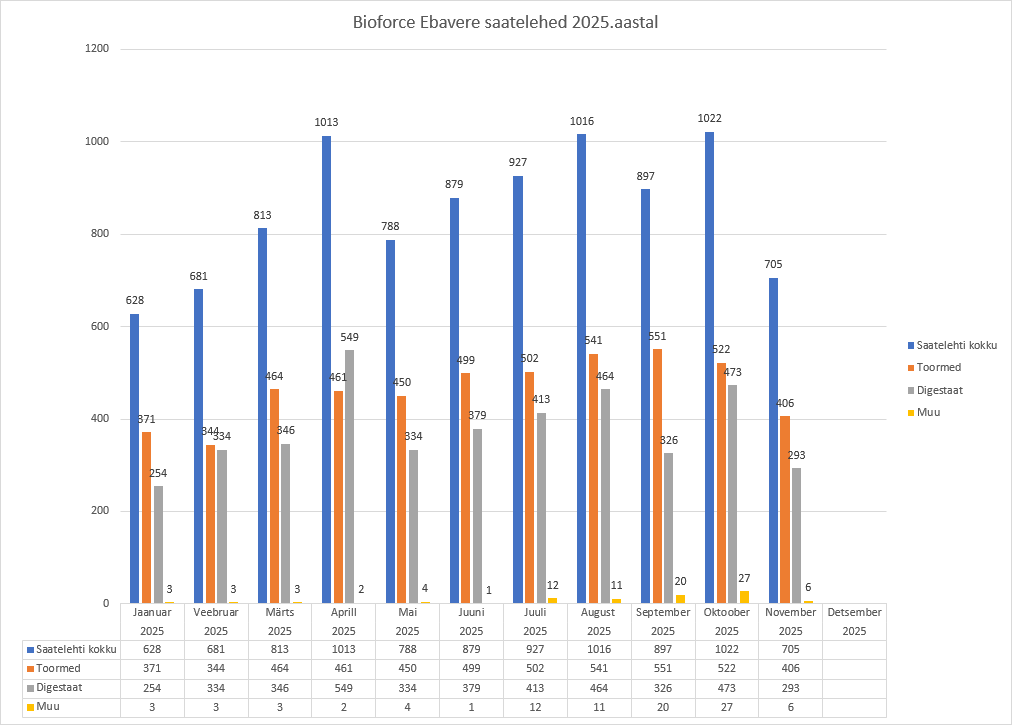

At Bioforce’s plants, nearly 1,300 waybills were filled out manually every month. This resulted in hundreds of paper documents, duplicate data entry, and a workflow vulnerable to human error. Daily logistics operations required precise scheduling, yet information was scattered across multiple Excel files. There was a clear need to consolidate all logistics data into a single database to reduce errors and improve process efficiency.

Before implementing Waybiller, the entire process was manual:

- Hundreds of paper documents and Excel files.

At the Ebavere plant, approximately 800-1,000 waybills were issued monthly, and at Laatre, 300–350. All documents had to be completed by hand and then entered into Excel, making the process time-consuming and prone to errors. - Duplicate data entry.

Plant operators had to record the same information both on paper and in Excel, leading to repeated work and a high risk of mistakes. - Delivery schedule coordination.

Bioforce transports raw materials in and biomethane or digestate out daily, seven days a week, for ten hours per day. Liquid and solid materials (slurry, manure, biomass) must be transported from storage facilities in close coordination with partners, requiring precise time management. - Lack of a central database.

All information was stored in separate Excel files. There was a strong need to merge a large number of standalone spreadsheets into one unified database.

Solution: Digital waybills with Waybiller

Bioforce joined Waybiller in February 2023, with Production Manager Marius Mets leading the project. The main expectations for Waybiller’s digital solution were to reduce manual work and reliance on Excel, and to create a central, reliable logistics database. The goal was to gain real-time visibility over all transports and make operations easier and more consistent for both Bioforce and its partners. Implementing Waybiller also supported growing transport volumes and ensured that logistics processes remained clear, transparent, and fully paperless. Figure 1 shows the distribution of e-waybills at Ebavere station in 2025.

Implementation Steps

System setup and data migration.

Existing Excel spreadsheets and paper documents were digitised. A key objective was to establish a central database consolidating all transport and raw material movements.

User training.

Training sessions were conducted for plant operators, partners, and drivers. According to Production Manager Marius Mets, there was some initial resistance, but consistent guidance helped both younger and older drivers adopt the system. Where necessary, tablets were installed in trucks to enable drivers to use the Waybiller platform and create e-waybills.

Partner onboarding.

Bioforce set a clear requirement for suppliers to use the Waybiller system. This ensured data consistency and eliminated the need for paper delivery notes at partner companies.

Digitisation of waybills and delivery scheduling.

Every transport (both inbound raw materials and outbound biomethane or digestate) is now recorded using an electronic consignment note. Waybiller enables the creation and sharing of real-time delivery schedules, reducing phone communication and keeping all parties informed.

The e-waybill solution plays a crucial role in Bioforce’s logistics processes. Raw material supply chain manager Marius Mets summarised the impact as follows: “Waybiller is the only reasonable logistics database. Previously, we relied on manually filled Excel spreadsheets. With Waybiller, that annoying data entry work is gone. I truly believe in Waybiller.”

Results and Benefits

Implementing Waybiller significantly reduced manual work and errors, delivering substantial time savings for plant operators and making the entire logistics chain more transparent and automated. Real-time data, reduced paper and Excel usage, and smoother collaboration benefited both Bioforce and its partners. At the same time, a digital and scalable system provides a strong foundation for Bioforce’s future growth and the efficient launch of new plants. Key results:

- Time savings and reduced labour costs.

Plant operators no longer need to fill out Excel spreadsheets, as digital waybills automatically store all data. This saves significant time and allows employees to focus on their core tasks. - Real-time data and increased transparency.

Through Waybiller’s e-waybills, Bioforce employees, suppliers, and customers can view all transports in real time. This improves delivery reliability and reduces phone-based coordination. - Fewer errors.

Eliminating manual data entry reduced duplicate entries and human error. Data such as weighing results flows automatically into waybills and can be exported when needed. - Higher partner satisfaction.

Partners appreciate the speed and simplicity of the digital system, which reduces paperwork and Excel usage. Younger drivers, in particular, see digital waybills as a natural part of their daily workflow. - Reduced paper use and a greener footprint.

Bioforce’s mission is to produce green fuels and reduce CO₂ emissions. The introduction of digital documents significantly reduces paper consumption, eliminating thousands of paper sheets annually and aligning well with circular economy principles. - Growth readiness.

As Bioforce plans to produce nearly 600 GWh of biomethane annually by 2028 with new plants, a scalable digital logistics platform is essential. Experience with Waybiller ensures that new facilities can operate digitally from day one.

Key Logistics Metrics: Before and After Digitalisation

| Metric | Before Waybiller | After Waybiller |

| Waybills (Ebavere & Laatre) | ~1,300 paper waybills/month (Excel entry required) | ~1,300 e-waybills; automated data flow and central database |

| Data entry | Double entry (paper + Excel) | Single entry; data created digitally and stored directly in the system |

| Delivery reliability | Coordination via phone calls and Excel | Real-time schedules and notifications in Waybiller |

| Partner engagement | Skepticism: the digital system is not used | All partners and drivers use the e-waybill platform |

| Environmental impact | High paper usage; slow processes | Less paper; faster and more environmentally friendly |

Future Outlook and Conclusions

Bioforce is moving towards a fully integrated digital platform that consolidates all production and logistics data into a single database, improving reporting and quality management. New plants are planned to launch with digital logistics from the outset. Next steps in digitalisation:

Unified database.

Plans include creating a comprehensive database combining production and logistics data to simplify reporting, quality management, and investment planning.

New plants and increased volumes.

With new plants coming online, Bioforce aims to reach 600 GWh of biomethane production by 2028, potentially covering the entire natural gas demand of Estonia’s transport sector. All future plants will start with digital logistics.

Additional integrations.

The system is planned to integrate with production and quality equipment so that data such as dry matter content or laboratory results are automatically linked to waybills. This will improve digestate composition management and nutrient return to agriculture.

Summary

Bioforce’s experience confirms that digitalisation is a critical step in sustainable energy production. Implementing Waybiller reduced paperwork, improved logistics transparency, and freed up employee time. At the same time, Bioforce continues to invest in new biomethane plants and is actively working towards its climate and energy targets for 2028. This synergy between digital solutions and green energy production demonstrates how modern IT supports circular economy goals, turning farm waste into clean biomethane for transport fuel.

If you would like to start your journey towards a more digital and greener future, contact us via the “Sign up” form on our website or at support@waybiller.com, and we will help you find the best solution.